Textures and Finishes

Understand the Difference and Choose Your Favorite

When designing your ring ring, finish and texture play a key role in its overall look and feel. While they may seem similar, they have distinct meanings.

Texture refers to how the surface of the ring feels to the touch—some rings may have a rough, hammered, or brushed texture, while others feel smooth.

Texture refers to how the surface of the ring feels to the touch—some rings may have a rough, hammered, or brushed texture, while others feel smooth.

Finish, on the other hand, describes the surface treatment, such as polished, matte, or satin. A polished finish gives a shiny, reflective look, while a matte or satin finish creates a softer, muted effect.

Over time, textures and finishes evolve with wear. A rough texture may gradually smooth out with daily use, while a polished finish may develop fine scratches that give it a softer appearance. This natural aging process adds character to the ring, making it uniquely yours. However, if you prefer to maintain the original look, most rings can be refinished to restore their texture and shine.

At Krikawa, we offer a variety of textures and finishes that can be customized to match your style. Whether you prefer a rustic, handcrafted texture or a sleek, high-polish finish, our design consultants can help you choose the perfect combination. If your ring ever needs a refresh, refinishing services can bring back its original beauty, ensuring it remains as stunning as the day you first wore it.

High Polish

Click here for a high-quality video

Machine Brushed

Click here for a high-quality video

Matte Finish

Click here for a high-quality video

Stone Brushed

Click here for a high-quality video

Stone Washed

Click here for a high-quality video

Crosshatch

Click here for a high-quality video

Machinist

Click here for a high-quality video

Round Hammer

Click here for a high-quality video

Long Hammer

Click here for a high-quality video

Millegraining

Millegraining is a decorative technique in which, historically, a little roller is rolled over edges to give the appearance of tiny round balls. Contemporary millegraining is done two ways: Larger beads are cast in place, for a larger look and a more affordable price (shown on left), or the traditional wheel is used for true millegraining (shown on right). Both can look great! It just depends upon the final look you are trying to achieve.

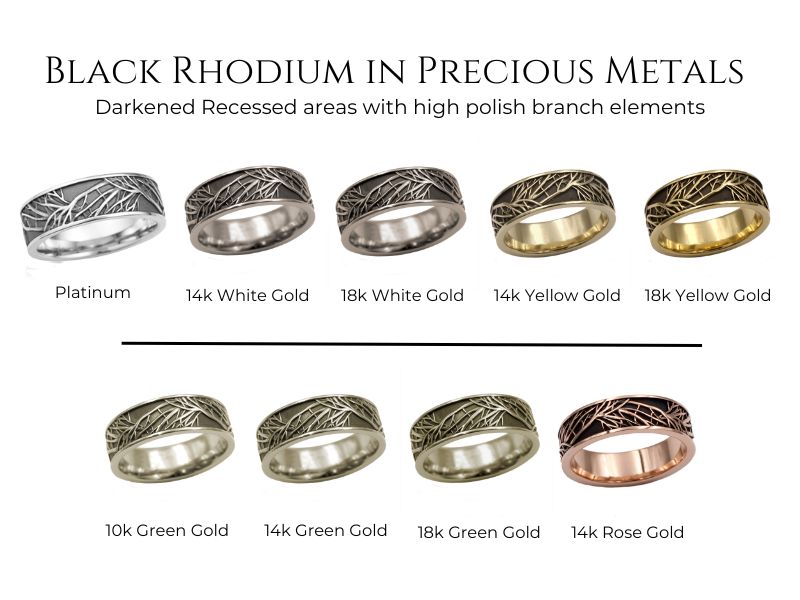

Black Rhodium Plating (aka Charcoal or Gunmetal plating)

A darkened finish is superficial and completed by electroplating with Black Rhodium. How dark a piece gets depends on the metal. Black Rhodium will not be dark as a "black leather jacket", but the difference between natural and darkened metals ranges from subtle to quite distinct.

Yellow or rose gold will achieve a dark, charcoal color.

White or green gold will be closer to gunmetal gray, so not as dark.

Platinum will not darken and the result is a muted gray.

Black Rhodium is a coating of metal over the surface and may fade over time. It has the most longevity in recessed areas of rings, where surface contact is less likely. If the original metal color ever starts showing through, the ring can be re-plated with Black Rhodium.

Precious Metals and How Darkened Finishes Look

Please note: We do not recommend Black Rhodium on the raised areas of a ring (or over the entire surface of a ring), as the darkening can quickly wear off. The ring in the image on the right has been entirely plated with Black Rhodium. The look will wear much faster exposing the natural metal color.